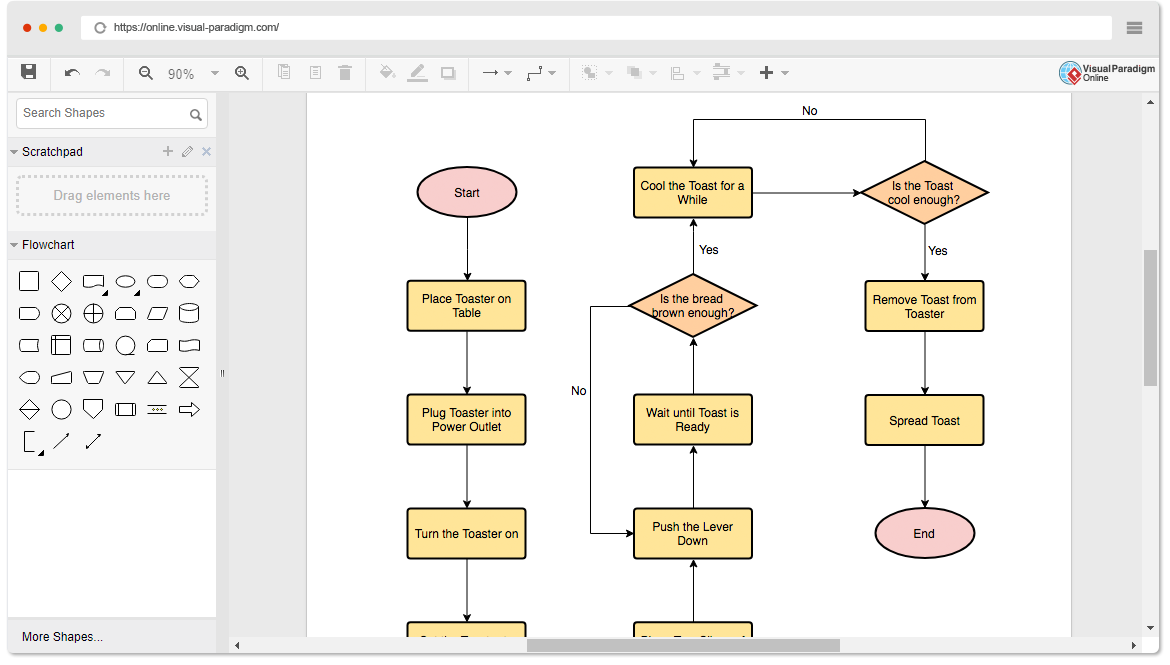

This model will concentrate on a particular sector/area of a chemical plant. These documents would help orient workers to the products and important operation zones of a chemical facility (Peters and Timmerhaus, 2003). They will be generalized to certain plant sectors or stages. This model of flow diagram is used to explain the general material flows throughout an entire plant. The diagram is modeled below using arrows entering and exiting a process box to represent the inputs and outputs, respectively.įigure1. The simplest form of BFD, the I/O (input/output) diagram (Biegler et al., 1997), provides the material streams entering and exiting the process. They can be extremely simple or very detailed in their explanation of a process. These can be understood by people with little experience with reading or creating flow diagrams (Towler and Sinnott, 2013).īFDs come in many forms and styles. These models allow for the reader to get an overall picture of what the plant does and how all the processes interact. Once alternatives have been chosen, the BFD serves as a starting point for a complete process flow diagram (PFD).Ī BFD is a useful tool for reports, textbooks and presentations when a detailed process flow diagram is too cumbersome. Different alternatives can be easily and inexpensively compared at an early stage using simple BFDs. For a complex process, block flow diagrams can be used to break up a complicated system into more reasonable principle stages/sectors.Ĭreating a BFD is often one of the first steps in developing a chemical process. Blocks in a BFD can represent anything from a single piece of equipment to an entire plant. A BFD is the simplest form of the flow diagrams used in industry.

Ideally, the experiment would involve a large group of students, both taking the same test (such as two sections of a large class). To test whether red light worsens student test scores, you want to compare test scores from exams taken under normal lighting to those taken under red lighting. Experimental design is important because a poorly designed experiment can lead a researcher to draw the wrong conclusions. The next step is to design an experiment to test the hypothesis. The effect on student test grade is dependent on the lighting and is the dependent variable. For example, "If the classroom lighting is changed to red, then student will do worse on tests." The color of the lighting (the variable you control) is the independent variable.

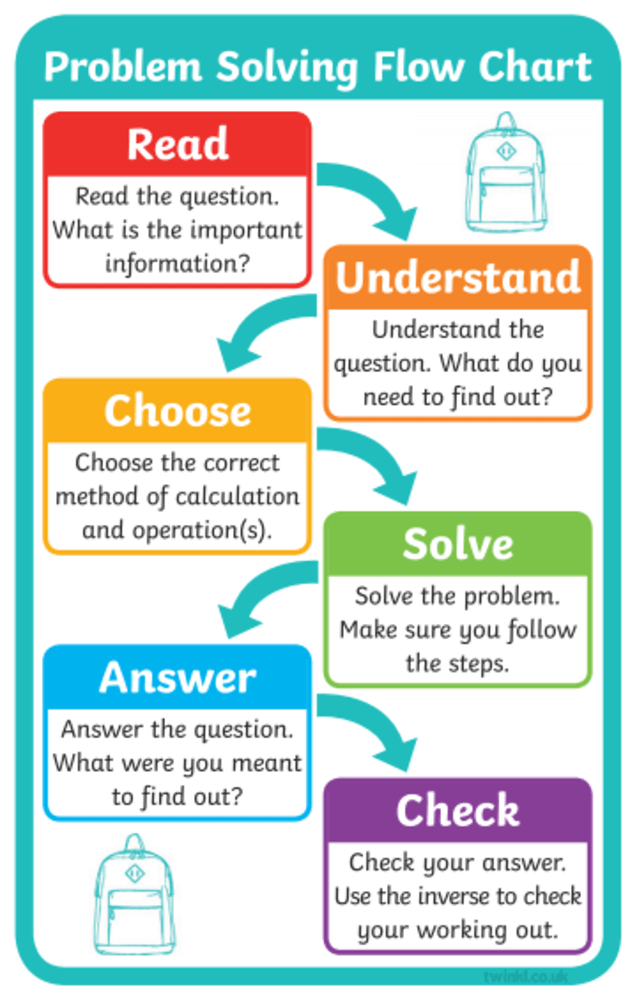

The hypothesis may be stated as an "if-then" statement. You measure what you think will change: the dependent variable. This "thing" that you change is called the independent variable.

This is a prediction of what you think will happen if you change one thing.

Ideally, you want to take notes of observations because this information may be used to help formulate a hypothesis.įollowing the flow chart arrow, the next step is to construct a hypothesis. Sometimes people omit this step from the scientific method, but everyone makes observations about a subject, even if it's informally. The first step in following the scientific method is to make observations.

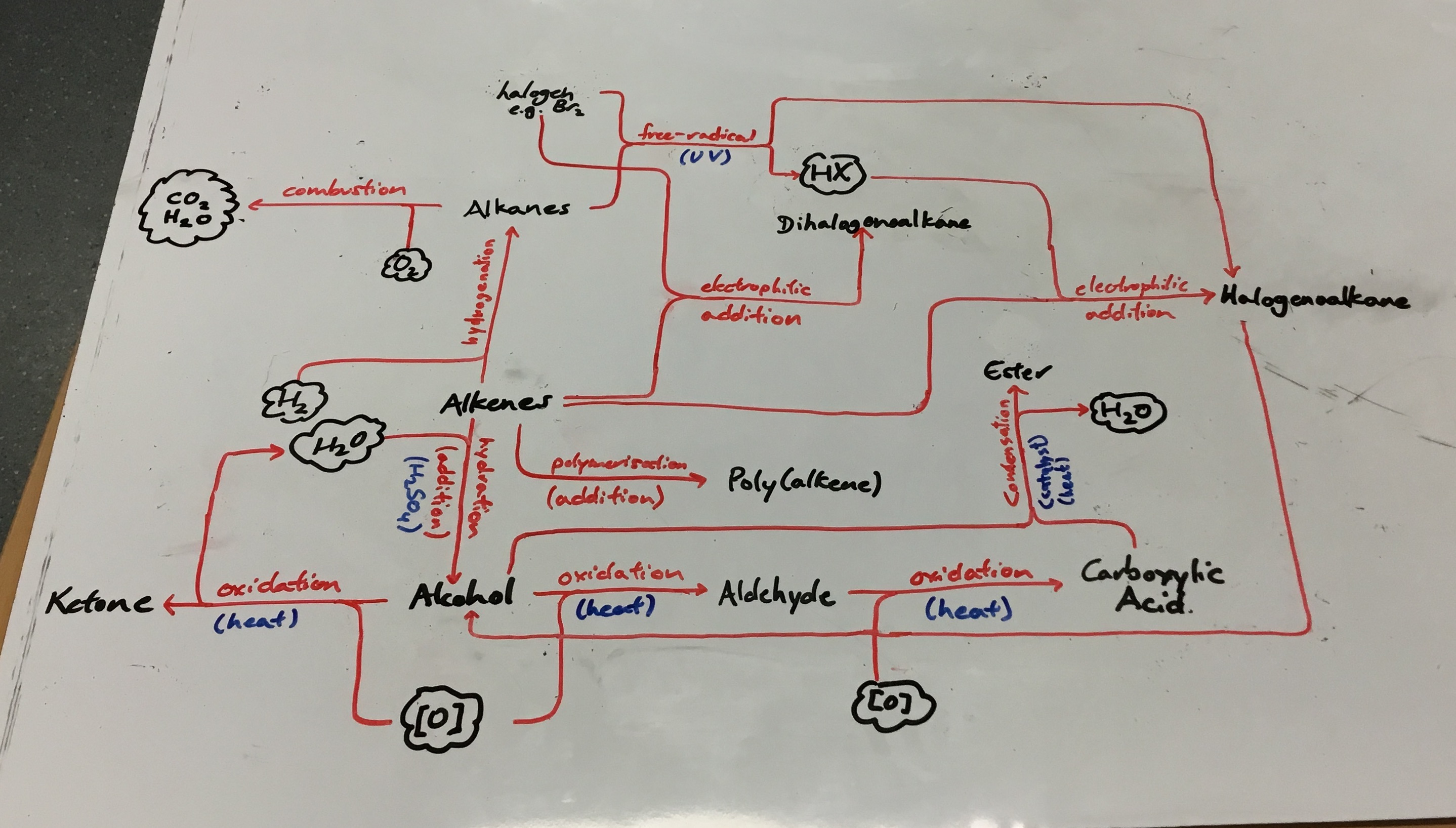

#CHEM DRAW MAKE A FLOWCHART HOW TO#

Example of How to Use the Scientific Method Flow Chart

0 kommentar(er)

0 kommentar(er)